Laser Cladding Explained

Laser cladding is the deposition of material onto a base part for the purpose of enhancing the mechanical properties of the component.

Direct Metal Deposition

Laser cladding is an advanced surface modification process where a high-powered laser melts a layer of metallic powder or wire onto a component’s surface. This technique is widely used for wear resistance, corrosion protection, and repairing damaged parts. Industries such as aerospace, oil and gas, and tool and die manufacturing benefit from laser cladding due to its minimal heat input, reducing distortion while achieving metallurgical bonding. The ability to apply controlled layers ensures optimal material usage, reducing waste and improving sustainability.

How Laser Cladding Works

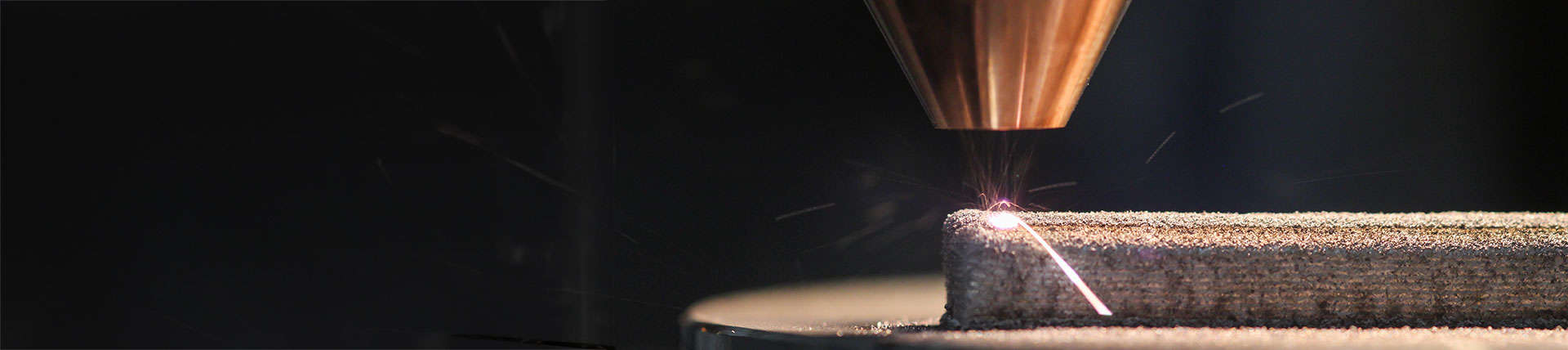

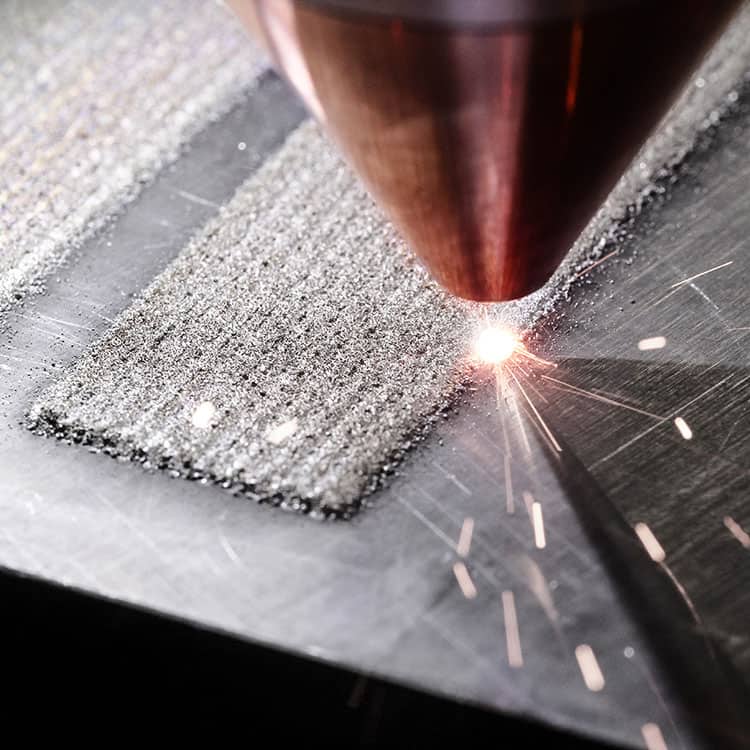

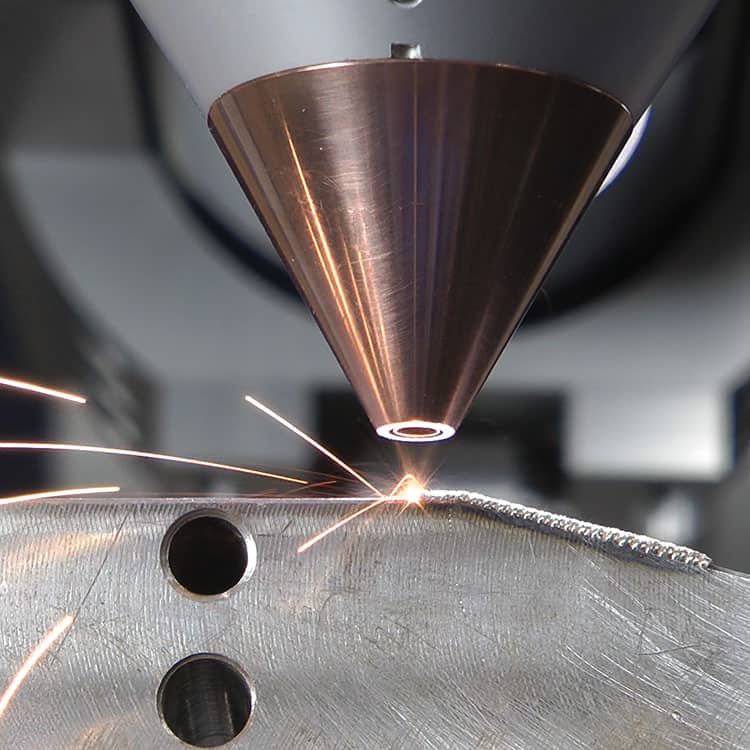

Laser cladding involves the use of a high-powered laser to create a concentrated heat source that melts a thin layer of metal powder or wire onto the surface of a component. The material is fed through a cladding nozzle, where the laser melts both the base material and the cladding material, creating a metallurgically bonded layer. This precise process allows for controlled deposition of material, ensuring minimal waste and exceptional accuracy.

A key advantage of laser cladding is its ability to deposit materials selectively, making it suitable for enhancing mechanical properties only where required, such as on high-wear areas of industrial components.

The Science Behind Laser Cladding: Direct Metal Deposition

Laser cladding utilises a process known as Direct Metal Deposition, where metallic powder or wire is fed through a specialised nozzle and melted by the laser beam as it contacts the workpiece. This creates a metallurgical bond between the deposited material and the base component.

The use of a laser enables precise energy control, limiting the heat-affected zone (HAZ) and reducing the risk of distortion. The high energy density allows for rapid material deposition while maintaining fine control over layer thickness.

The Alpha Laser cladding systems, equipped with a laser cladding nozzle, achieve powder efficiencies of up to 98% with deposition rates as high as 500g/h, making them ideal for large-scale applications where minimal material waste and high productivity are required.

TLM Laser Solutions for Laser Cladding

At TLM Laser, we provide advanced laser cladding systems from our parter Alpha Laser. Their systems offer industry-leading powder efficiency and deposition rates, making them ideal for industries requiring surface enhancement, repair, and precision coating solutions.

Our solutions are tailored to meet the diverse needs of UK and Ireland manufacturers, offering both standalone systems and integrated options suitable for large-scale production environments. Whether you’re looking for precision cladding for delicate components or large-scale industrial maintenance, TLM Laser provides the expertise and technology to enhance your operations.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.