Organics

Laser technology has quickly changed how industries work with organic materials. With beginnings from scientific research, it has evolved into a sophisticated manufacturing tool capable of manipulating materials with extraordinary precision. From intricate paper & card packaging to robust stone engraving, lasers now enable manufacturing processes that were unimaginable just a few decades ago. Modern laser systems represent a culmination of physics, engineering, and material science.

These technologies can cut, mark, engrave and a range of other industrial applications for organic materials with precision accuracy. Unlike traditional mechanical tools that physically contact and potentially damage materials, lasers offer a non-invasive approach to processing and are suited to work in tandem with modern manufacturing processes.

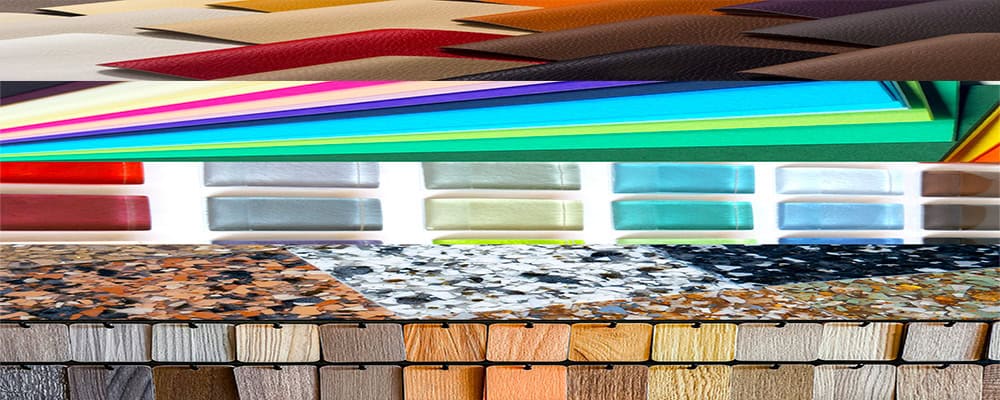

The Spectrum of Organic Materials

Whilst there are a multitude of what can be considered ‘organic’ materials, with many modern-day products potentially including several different types of organic materials, there can be a common problem of finding the best solution for each type of material. Laser technology has proven particularly effective in processing organic materials, each with its unique characteristics and industrial applications, with some of the most common materials used in commercial and industrial processes being paper & cardboard, leather, wood, rubber, stone and glass.

Advantages Of Using Lasers For Different Industries

- Paper & Cardboard:

- Packaging – Intricate packaging designs with small kerf widths

- Packaging – Scoring for tear-away tabs for easy-opening boxes

- Packaging – High-speed variable data printing in FMCG packaging

- Leather:

- Fashion – Precision cutting and engraving for the fashion industry for luxury leather goods like handbags

- Automotive – Similarly in automotive industries for car interiors with laser cutting and perforating for breathable upholstery

- Wood:

- Furniture Manufacturing – Modernising furniture manufacturing during the joinery stage and helping reduce assembly time

- Architecture & Interior Design – Architectural detailing, enabling designs and geometries that traditional methods find difficult to produce

- Rubber:

- Automotive – Enhanced traceability for tires with 2D laser marking as part of Industry 4.0 for modern manufacturing processing

- Automotive – Environmentally conscious laser cleaning of tire moulds, removing unwanted contaminants

- Stone:

- Stonemasonry – Simplifying the production of gravestones through laser engraving

- Conservation – Portable laser cleaning options in the conservation industry, helping preserve buildings and monuments

- Glass:

- Medical – Although inorganic, glass is often grouped with organics in laser processing applications, laser marking and engraving is often used in the production of medical and scientific research products like glass beakers and vials

- Automation of production lines to increase production volume with high levels of consistency and repeatability

Laser Types For Different Materials

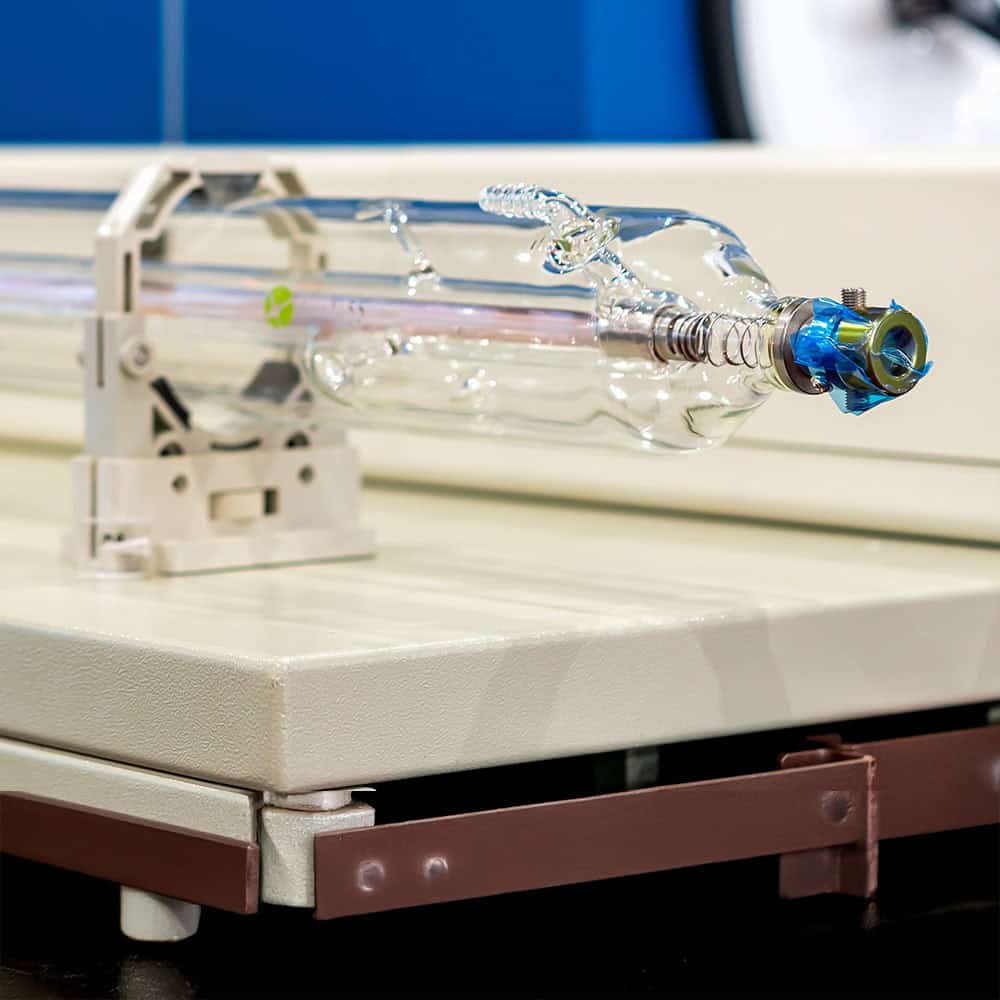

The effectiveness of laser processing stems from the interaction between light and matter. Different laser types are employed based on the material and desired outcome:

UV Lasers: Providing unique capabilities for processing certain plastics and for high-precision work on materials like glass with ‘cold marking’ due to the wavelength of the laser

CO₂ Lasers: Ideal for cutting and engraving most organic materials due to their wavelength’s high absorption in these substances.

Fibre Lasers: Offering high efficiency and precision, particularly useful for marking and engraving metals but also applicable to some organics.

Wavelength Compatibility:

- CO₂ (10.6 µm): Best for most organics (wood/leather) but struggles with metals/glass.

- Fibre (1 µm): Limited absorption in untreated wood/leather.

- UV (355 nm): Effective for glass (prevents micro cracks) but slower on thick materials.

Power vs Speed Trade-off:

High power (≥100W) risks burning; low power (<30W) prolongs processing.

Safety Constraints:

Organic materials often require Class 4 laser enclosures with appropriate fume extraction.

Key Considerations For Organic Materials Using Lasers

While organic materials like cardboard, wood, leather, and stone have been laser-processed for decades, their unique properties demand careful calibration of equipment and processes. Even with advancements in laser technology, certain challenges persist when working with these materials. Below, we outline key considerations for each material, including limitations and best practices.

| Material | Key Factors | Solutions |

|---|---|---|

| Paper & Cardboard | Thickness limitations, fire risk, adhesives | Use lower powered CO₂ lasers, opt for uncoated cardboard and use an air assist |

| Leather | Tanning methods, over-engraving, fume management | Use lower powered lasers, use low-frequency pulsing, carbon air filtration system |

| Wood | Density variations, resin content, grain direction | Seal surfaces with water-based coatings, use CO₂ lasers that have option for different power ratings |

| Rubber | Melting, fume control, rebound effect | Use nitrogen gas assist, consult on wavelength absorption for specific materials |

| Stone | Inconsistency, Low Contrast, Abrasion | Test settings on small sections, use fibre lasers for finer details |

| Glass | Cracking risk, low contrast legibility, wavelength dependence | Pre-treat with marking sprays, use pulsed UV lasers |

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.