Laser Processing for the Oil & Gas industry

In the demanding oil and gas sector, precision and durability are essential. TLM Laser provides advanced laser systems for marking, welding, cutting, and cleaning, enabling manufacturers to produce components that withstand extreme environments and meet industry standards.

Marking Systems for Traceability in Extreme Environments

TLM Laser supplies marking systems designed for high-stress environments in the oil and gas industry. These systems produce permanent, high-contrast marks on pipelines, valves, and drilling tools, ensuring compliance, traceability, and reliability under extreme conditions.

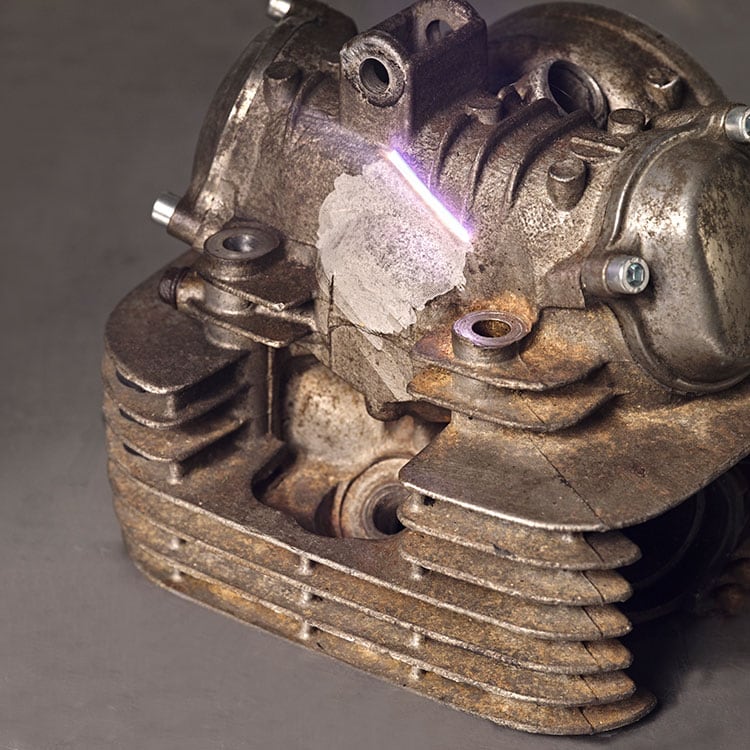

Welding High-Strength Connections for Oil & Gas Applications

Our laser welding systems enable manufacturers to create robust connections for oil and gas components, such as pipelines, pressure vessels, and structural supports. These machines deliver precise, corrosion-resistant welds that meet the demands of high-pressure, high-temperature environments. In addition, our welding systems provide the most reliable repair welds which are tried and tested in the harshest of environments.

Rust and Coating Removal for Pipeline Maintenance

TLM Laser offers cleaning systems that remove rust, coatings, and contaminants from oil and gas equipment, including pipelines and storage tanks. This non-abrasive process enhances the durability of components, ensuring optimal performance and reducing downtime during maintenance.

Cutting Complex Parts for High-Pressure Systems

Our laser cutting systems support the fabrication of intricate components used in oil and gas applications. From precision shaping of valve parts to cutting structural supports, these machines ensure high-quality results that meet the industry’s rigorous standards.

Innovate with Confidence

Laser Machines and Systems

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.