Talk to Us!

Connect with our Technical & Support Team.

Key Feature

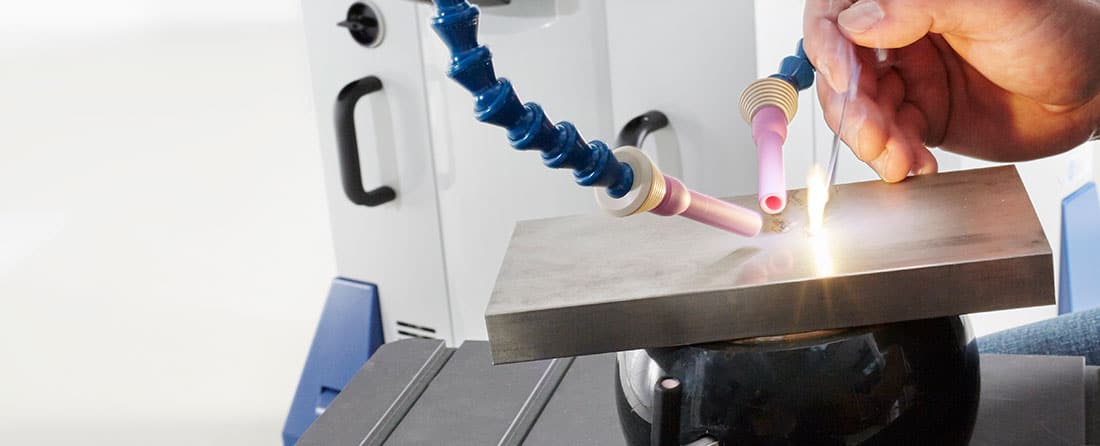

Laser Welding for Tool and Die Repair

Laser welding offers a crucial advantage in tool and die repair, significantly extending the service life of tools and dies whilst maintaining high precision and strength.

Information About Laser Welding

We offer two types of metalwork welding from ultra-precise micro welding to fabrication welding:

- Hand-held Fabrication Welding: Designed for versatility and portability, handheld fabrication welding is ideal for larger-scale welding applications requiring flexibility. Allowing for quick, efficient joining of metals with minimal setup or training, this technology is taking over within general manufacturing.

- Precision Welding: This application specialises in ultra-fine, detailed welding for small-scale applications, such as intricate medical devices, electronic sensors, or jewellery pieces. With pinpoint control, these systems deliver unmatched accuracy for delicate or high-precision projects.

Laser Welding for UK Industries

Laser welding offers solutions across a wide range of industries, meeting demanding requirements for strength, durability, and precision. From large-scale manufacturing to intricate component welding, our systems deliver unmatched results.

Create precise, contamination-free welds for medical devices and instruments, ensuring safety and compliance.

Learn MoreAchieve reliable, high-strength welds that meet stringent aerospace standards for critical components.

Deliver durable welds for automotive parts, enhancing performance and safety.

Ensure robust welds for heavy-duty machinery, improving durability and efficiency.

Weld intricate components with precision, maintaining functionality and integrity.

Create seamless, delicate welds for intricate designs and custom jewellery.

Weld components to withstand extreme conditions in pipelines and equipment.

Deliver corrosion-resistant welds for marine applications, ensuring longevity.

Enhance tool and die durability with precision laser welding.

Ensure reliable welds for rail infrastructure, meeting industry safety standards.

Laser Welding Materials

From plastics to metals, laser welding provides precise, efficient joining solutions tailored to the unique requirements of different materials.

Achieve strong, high-quality welds on a wide range of metals, from steel to aluminium.

Laser welding provides precise, clean joins for various plastics, ideal for sensitive applications.

Answering Your Questions

Frequently Asked Questions

Precision micro welding focuses on joining small, delicate components with high accuracy, making it ideal for industries like electronics and medical devices. In contrast, hand-held laser welding offers flexibility and portability, allowing operators to weld larger, more complex, or immobile workpieces across various industries, including automotive, aerospace, and construction. The choice between the two methods depends on the specific requirements of the application, such as component size, precision, and accessibility.

Hand-held laser welding systems offer several benefits, including flexibility, portability, and ease of use. These systems allow operators to perform precise welds on large, complex, or immobile workpieces that are difficult to process with stationary equipment. Hand-held laser welders are suitable for various materials and thicknesses, providing high-quality welds with minimal heat input and distortion.

Precision micro welding is a laser welding technique that enables the joining of small, delicate components with high accuracy and minimal thermal distortion. This process is ideal for industries requiring fine detail and precision, such as electronics, medical devices, and aerospace. Typical applications include welding fine wires, miniature components, and intricate assemblies where traditional welding methods may be too aggressive.

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.