Laser Fume Extraction

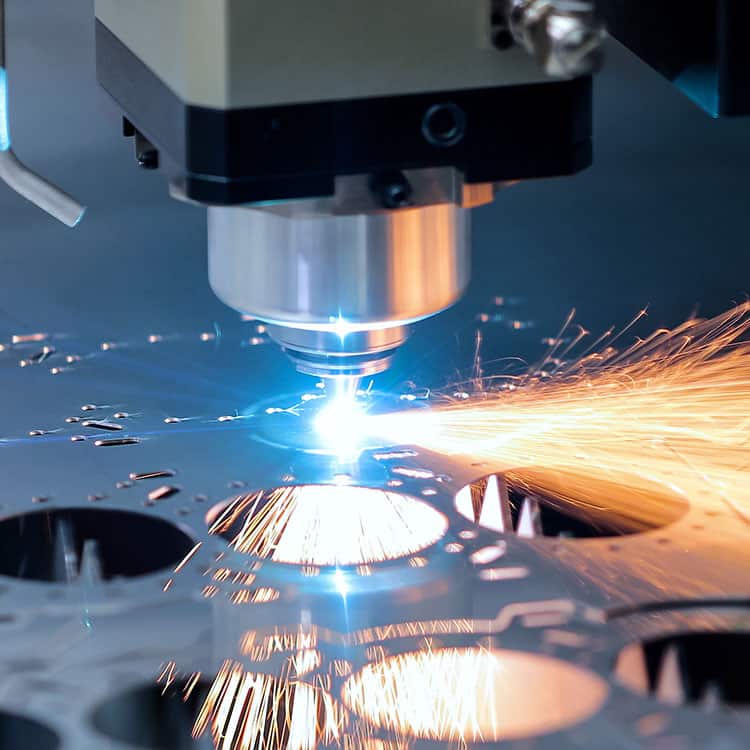

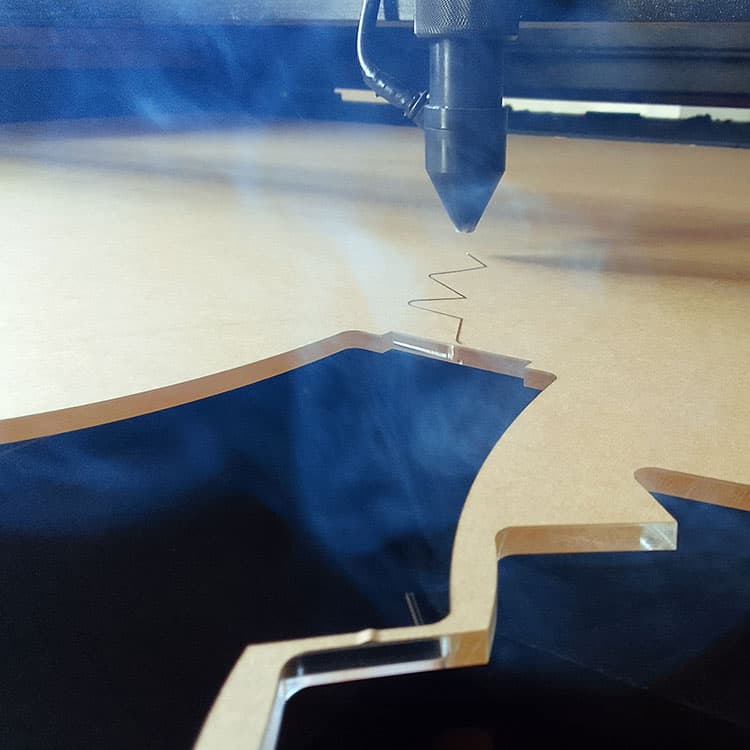

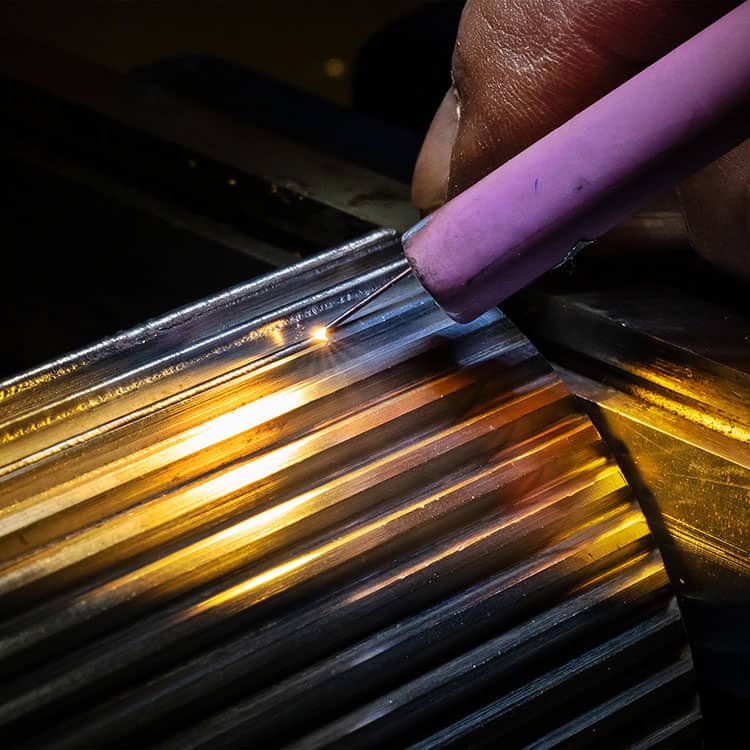

Laser processes—whether marking, welding, cutting, or engraving—generate hazardous fumes and particulates that pose serious risks to health, safety, and system performance.

Protecting Health, Safety, and Productivity in Laser Applications

TLM Laser, in partnership with BOFA, the global leader in fume extraction technology, offers advanced solutions to capture and filter Laser Generated Airborne Contaminants (LGACs). From safeguarding your workforce to extending the lifespan of your equipment, our BOFA extraction systems deliver unrivalled efficiency and compliance with safety regulations.

The Hidden Dangers of Laser Fumes

Why Laser Fume Extraction Matters

Laser processes release a combination of sub-micron particulates and toxic gases. While materials like metals produce primarily fine particulates, non-metals such as plastics and wood emit dangerous Volatile Organic Compounds (VOCs), including carcinogens like formaldehyde and benzene.

Without proper extraction, these contaminants can:

- Cause respiratory issues, allergic reactions, and long-term health problems.

- Damage sensitive laser optics by burning particulates into the lens, reducing system efficiency and precision.

- Contaminate products, particularly in open-container marking applications.

- Lead to legal compliance issues under regulations like COSHH, HSE, and ISO standards.

BOFA

The Global Leader in Fume Extraction

As the UK distributor for BOFA International, TLM Laser provides a full range of laser fume extraction systems tailored to your specific applications. BOFA’s advanced technology ensures the highest levels of filtration, safety, and efficiency for any laser process.

Three-Stage Filtration for Complete Protection

BOFA extraction units utilise a highly efficient three-stage filtration process:

- DeepPleat Pre-Filters: Capture larger particulates to protect HEPA filters.

- HEPA Filters: Remove 99.997% of particulates at 0.3 microns or smaller.

- Chemical Filters: Use activated carbon to neutralise VOCs, odours, and hazardous gases.

Key Features of BOFA Extraction Systems

- Intelligent Monitoring: Real-time filter status, airflow readings, and diagnostics to ensure optimal performance.

- Automatic Flow Control (AFC): Maintains consistent airflow for different applications, reducing noise and protecting filters.

- Remote Connectivity: BOFA’s iQ2 system offers cloud-based monitoring, field bus connectivity, and advanced diagnostics for maximum uptime and control.

- Energy Efficiency: Reduced running costs through smart filtration management.

Applications for Laser Fume Extraction

BOFA systems are suitable for a wide range of laser processes across industries:

- Laser Cutting: Effective removal of high levels of particulates and VOCs, such as those generated by MDF, plastics, and composites.

- Laser Welding: Capture of toxic fumes produced during plastics and metals welding.

- Laser Marking & Engraving: Safe removal of contaminants, protecting operators and product quality.

- Laser Ablation: Capture of airborne materials from surface coating removal.

Why Choose TLM Laser for Fume Extraction?

- Compliance and Safety: Ensure your workplace meets COSHH, HSE, and ISO safety standards.

- Tailored Solutions: We help you select the right BOFA system for your laser process, material, and environment.

- Expert Support: From installation to ongoing maintenance, our team ensures your extraction system runs smoothly.

- Improved Productivity: Protect your equipment, reduce downtime, and enhance product quality with effective fume extraction.

Choosing the right extraction system is critical to maintaining safety, compliance, and operational efficiency. At TLM Laser, we combine our expertise with BOFA’s innovative technology to provide tailored solutions for any laser application.

Answering Your Questions

Frequently Asked Questions

Ensuring compliance starts with a proper risk assessment, appropriate safety measures, and operator training. TLM Laser provides safety audits, guidance on protective equipment, and training courses to help businesses meet UK and EU laser safety standards. We can also advise on laser enclosures, fume extraction, and interlock systems to keep your workplace safe and compliant.

TLM Laser offers certified laser safety training tailored to different levels of expertise. Our offerings cover laser classifications, risk assessments, safety controls, and best practices to ensure compliance with UK and EU regulations. Whether you need training for new staff or refresher courses for experienced operators, we provide hands-on and theoretical instruction to improve workplace safety.

Laser systems can pose risks such as eye and skin exposure, fumes, and fire hazards if not handled properly. Following laser safety regulations ensures compliance with health and safety laws while protecting operators from potential harm. Implementing the correct safety measures, including training, protective equipment, and system safeguards, is essential for a safe working environment.

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.